Ideal for Pharmaceutical, Nutraceutical, Food and Chemical industries

Designed for your blending needs for all free-flowing solids

Efficient blending with no material accumulation; enabling easy discharge

Supports liquid addition with high speed intensifier bars

Available in mobile, tabletop configuration to large scale production units

Customizable Features:

- Small batch capacity (2-44) qt

- Liquid addition

- CIP system

- Intensifier bar

- Production capacity (5-125) cubic ft

- Valve type

- Material type (304/316)

- Finish

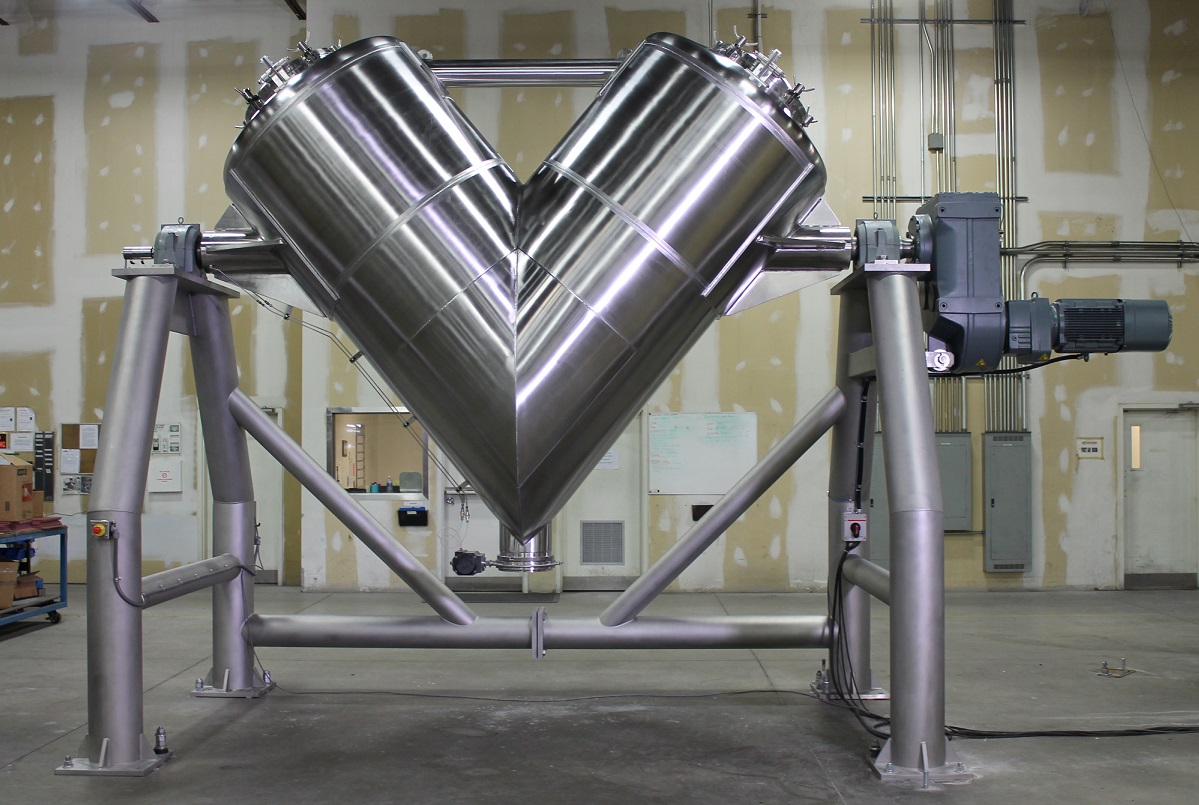

Stainless Steel V-Blenders

Full Description:

Blending powder ingredients is a major process in multiple industries. Unlike a mixers for liquids, V-blenders are designed to blend free-flowing solids into a single compound. Ability Fabricators specializes in producing high-quality services and products for any company that needs them. We’re dedicated to finding or designing the right product for you.How V-Blenders Work

V-blenders utilize gravity and tumbling to gently mix solid materials into a uniform substance. The V-shape allows the compounds to merge and separate via axial flows, combining when the V filters at the bottom and separating when it’s upside-down. This is a rapid process to mix materials without the use of any spinning blades or other mechanisms which could damage the materials. As long as the blender isn’t filled beyond where the V-shape separates, it will mix the substances thoroughly. V-blenders can also be made more versatile with the implementation of liquid-addition systems and intensifier bars.Why Stainless Steel?

Stainless steel is commonly used throughout manufacturing and commercial industries. It‘s the most common material used in the production of V-blenders for a variety of reasons. Stainless steel is easy to clean as its glossy finish provides a smooth surface that can be easily wiped down and sanitized. Additionally, it is non-corrosive which is particularly important in V-blenders as they are often used to mix dangerous, corrosive materials. Furthermore, stainless steel is heat resistant which is important when mixing high-temperature compounds or any combustible substances. It also has a high tensile yield strength of 215 MPa, making it safe for heavier substances without risk of damage.When Would You Use a Stainless Steel V-Blender?

Stainless steel V-blenders are ideal for Pharmaceutical, Nutraceutical, Food, Cosmetic and Chemical industries - all of which Ability Fabricators specialize in. The hygienic qualities of stainless steel reduce the risk of sanitary concerns for the products created in these industries, while the gentle tumbling method is perfect for mixing sensitive chemical and medicinal compounds. Engineered to ensure an efficient homogeneous mix of solids, V-blenders create a thorough blending of materials. They also ensure no material accumulation of unmixed substances and enable easy discharge of the finished product through the outlet via the discharge valve.Custom Stainless Steel V-Blenders

Depending on your industry and the intended use of your V-blender, you may need a custom model to meet your needs. We at Ability Fabricators provide these customized blenders for any commercial or industrial business. Here are some of the customizable features we offer to fit your specifications:- Small batch capacity: Our custom blenders are available in any size from tabletop configurations to large-scale production units, ranging anywhere from 2 to 44 quarts.

- Liquid addition: We provide an optional feature to add liquid at any point of the mixing process through the use of a liquid spray.

- CIP systems: We offer CIP systems to automate the cleaning process between batches, reducing maintenance time and maximizing efficiency.

- Intensifier bars: For those harder, sturdier materials that require more breaking up, we can fit your blender with intensifier bars for more optimal and thorough mixing.

- Production capacity: Our varied model sizes enable you to produce materials anywhere from 5 to 125 cubic feet to suit your needs.

- Valve type: Our customized models can be fitted with a valve type of your choice for the ideal speed and amount of substance release.

- Material type: Depending on the heat of your substances and the necessary chemical resistances, you may require stainless steel 316 over stainless steel 304. We can produce your blender with either.

- Finishes: We provide a custom finish, anywhere from 120 to 320 grit to give your blender the texture and appearance you desire.